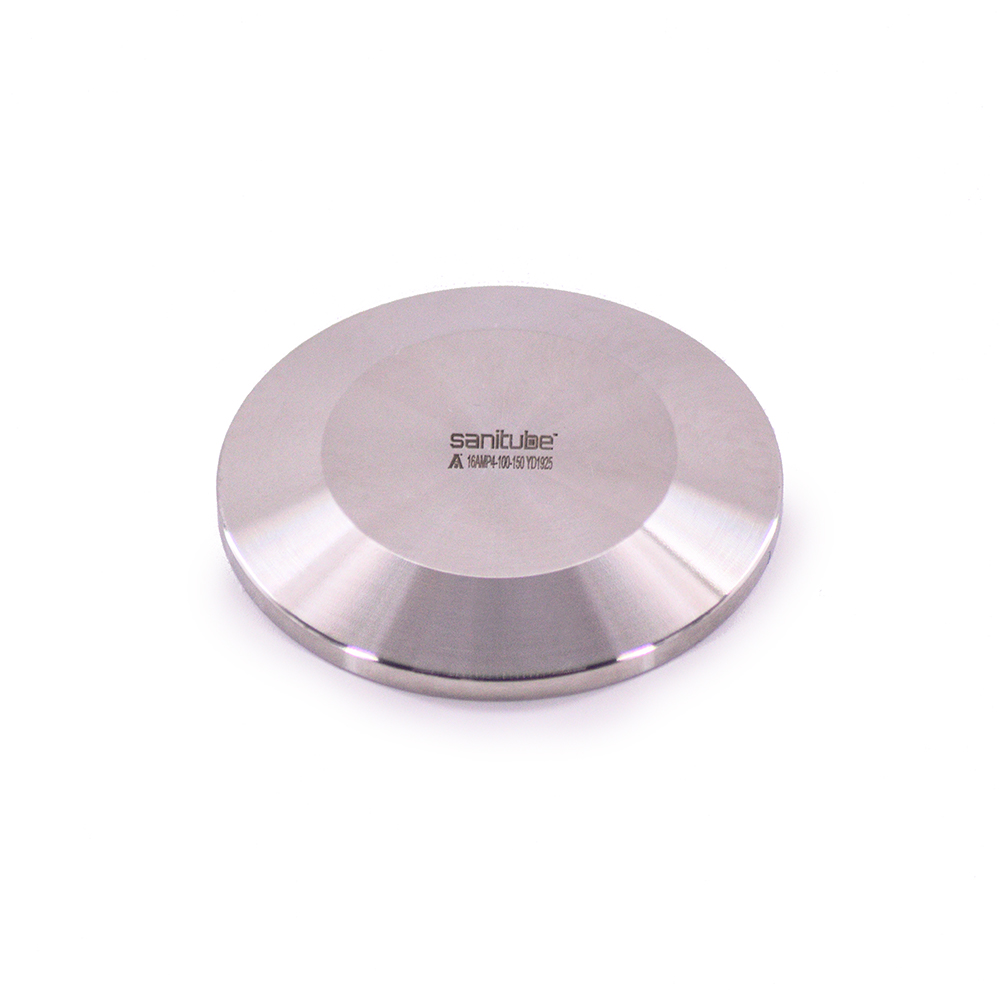

Facilitate secure, leak-proof connections with our Tri-Clamp fittings, featuring 90° elbows, tees, reducers, and more. Crafted from high-quality 304 and 316L stainless steel, these fittings meet 3-A Sanitary Standards, ensuring optimal hygiene and durability.

Sanitary Tri-Clamp tube fittings are widely used in the food and beverage industry, particularly in Food Processing Plants, Breweries, Wineries, and Dairies. Also known as

Tri-Clover fittings, they connect to the process line with a gasket, a clamp, and another quick-clamp fitting. They disconnect just as easily for cleaning or replacement.

What’s the difference between Tri-Clamp and Tri-Clover? The answer is simple. They’re identical in every way. “Tri-Clover” was Alfa-Laval’s trademark for their sanitary clamp fitting type, and much like any pioneering product, their brand name became commonly used in the industry to describe any fitting with that connection type. Other manufacturers entered the marketplace and called their products “Tri-Clamp”, which is now the term in wider use. Your Tri-Clamp and Tri-Clover fittings will connect perfectly because they’re one and the same.

A Heavy-Duty or High-Pressure

clamp is used to complete the union between two Tri-Clamp fittings. In addition to choosing the correct clamp based on your temperature and pressure requirements, it’s very important to choose the right

gasket and make sure it’s properly seated before tightening the clamp. Improper alignment is a leading cause of leaks and contamination. The clamp should be secure, but not overtight. If the gasket bulges, it could push into the process line, creating space for bacteria to breed.

Below are the commonly used

gasket types offered by DuvaSanitary.com.

- Buna – Rubber gaskets for general purpose industrial sealing at moderate temperatures (between -22° and 250°F).

- Viton® – Rubber gaskets providing indefinite seal from 5° to 400°F, and an excellent seal at 600°F up to 48 hours.

- EPDM – A very stable rubber-like gasket that resists heat, oxidation and aging, with flexibility at low temperatures. Working range is -60° to 300°F.

- Teflon® – Also known as PTFE, these chemically resistant plastic gaskets are unaffected by most corrosive liquids and gasses from -400° to 500°F.

DuvaSanitary.com offers

Sanitary Tri-Clamp tube fittings in 304 and 316 stainless steel. With a polished ID to 32RA or better, sanitary fittings help to prevent impurities from settling and corrupting your medium. Our clamp end fittings meet all 3-A requirements.