Always Free Shipping on orders over $150

Achieve permanent welded connections with our Butt Weld fittings, including 45° and 90° elbows, tees, reducers, and crosses. Ideal for systems requiring robust, fixed joints for change of direction, these fittings are available in both 304 and 316L stainless steel, adhering to 3-A Sanitary Standards.

Sanitary Butt Weld fittings are widely used in the food and beverage industry, particularly in Food Processing Plants, Breweries, Wineries, and Dairies. Conforming to conventional tube OD specifications, our polished weld end fittings make a flush connection that permits smooth flow through a process line. Sanitary Butt Weld tube fittings are best used in permanent installations where equipment can be cleaned in place (CIP) and removal from the system is not required.

Butt weld fittings are used to perform a number of functions in a process line. They can reduce or expand the ID of the line, change the direction of flow, split a line into two or more branches, or combine two or more sections of the line at a junction point. Other types of sanitary fittings (clamp fittings, etc.) have joints were turbulence can occur as the tube medium passes.

Sanitary Butt Weld tube fittings, by comparison, will allow medium to flow unimpeded because there are no gaps between the two welded segments. Also, the absence of a gasket eliminates spaces or pockets where bacteria can develop, which is a clear benefit in processing plants where even the slightest corruption could be catastrophic.

The most commonly used sanitary Butt Weld fittings are elbows, reducers, tees, and caps. DuvaSanitary.com offers Sanitary Butt Weld tube fittings and more, in 304 and 316 stainless steel, in a wide range of shapes and sizes, all produced by manufacturers known for impeccable standards of quality. With a polished ID to 32RA or better, sanitary fittings will help to prevent corruption in your process line. Our fittings meet all 3-A requirements and are also available in BioPharm (BPE) fittings.

Whatever your requirement, DuvaSanitary.com is here for you. We are fast, reliable, and always keep you up to speed on the status of your order. Whether you need a consultation, or simply want to place an order online, DuvaSanitary.com is the resource you can trust.Products

Products

Showing all 22 resultsSorted by popularity

-

Select options This product has multiple variants. The options may be chosen on the product page

-

Polished Butt Weld End Cap – Stainless Steel – 16W

Price range: $7.50 through $444.45Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld Concentric Reducer – Stainless Steel – 31W

Price range: $8.75 through $1,057.75Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld 90° Elbow with Tangents – Stainless Steel – L2S

Price range: $9.70 through $327.25Select options This product has multiple variants. The options may be chosen on the product page -

Tube OD x Schedule 10s Weld Adapter – Stainless Steel – 19WX

Price range: $24.70 through $190.15Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld Long Tee – Stainless Steel – 7WL

Price range: $10.60 through $2,960.65Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld 45° Elbow – Stainless Steel – 2WK

Price range: $5.65 through $1,436.95Select options This product has multiple variants. The options may be chosen on the product page -

Male NPT x Tube OD Weld Adapter – Stainless Steel – 19WB

Price range: $13.35 through $188.75Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld Eccentric Reducer – Stainless Steel – 32W

Price range: $11.45 through $1,278.50Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld Lateral Wye – Stainless Steel – 28WA

Price range: $68.20 through $1,226.85Select options This product has multiple variants. The options may be chosen on the product page -

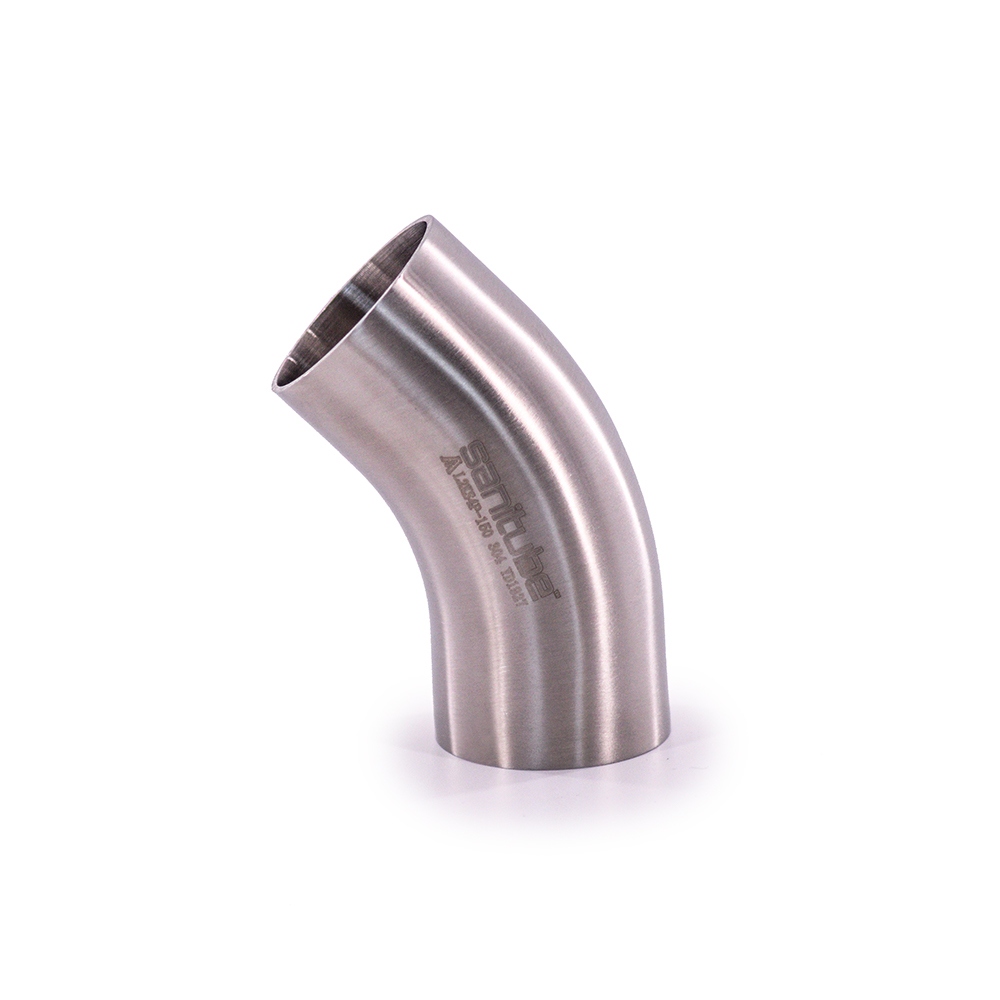

Butt Weld 45° Elbow with Tangents – Stainless Steel – L2KS

Price range: $10.85 through $341.00Select options This product has multiple variants. The options may be chosen on the product page -

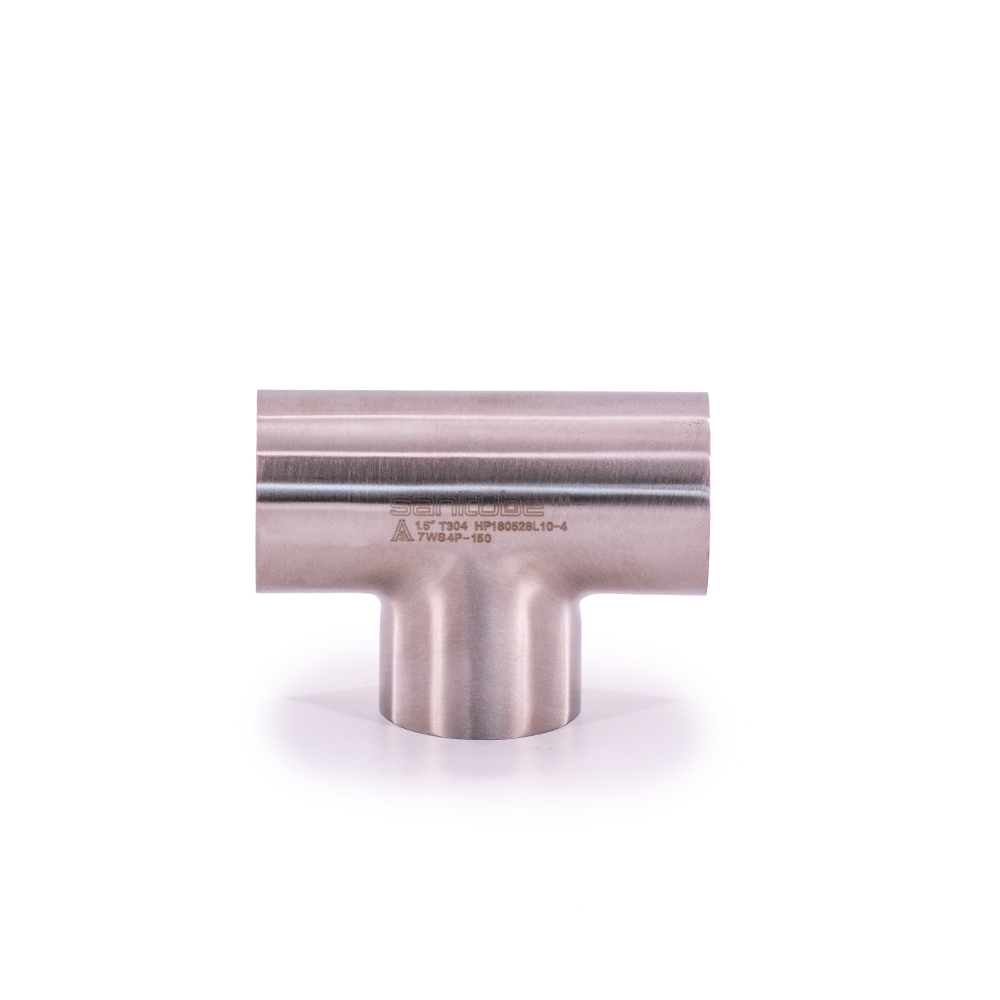

Butt Weld Short Tee – Stainless Steel – 7WS

Price range: $17.80 through $98.25Select options This product has multiple variants. The options may be chosen on the product page -

90° Automatic Weld Elbow – Stainless Steel – AW2S

Price range: $37.15 through $231.00Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld True Wye – Stainless Steel – 28W

Price range: $103.05 through $1,298.30Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld Reducing Tee – Stainless Steel – 7WRT

Price range: $19.30 through $3,318.85Select options This product has multiple variants. The options may be chosen on the product page -

Tube OD x Schedule 40s Weld Adapter – Stainless Steel – 19WZ

Price range: $82.55 through $384.65Select options This product has multiple variants. The options may be chosen on the product page -

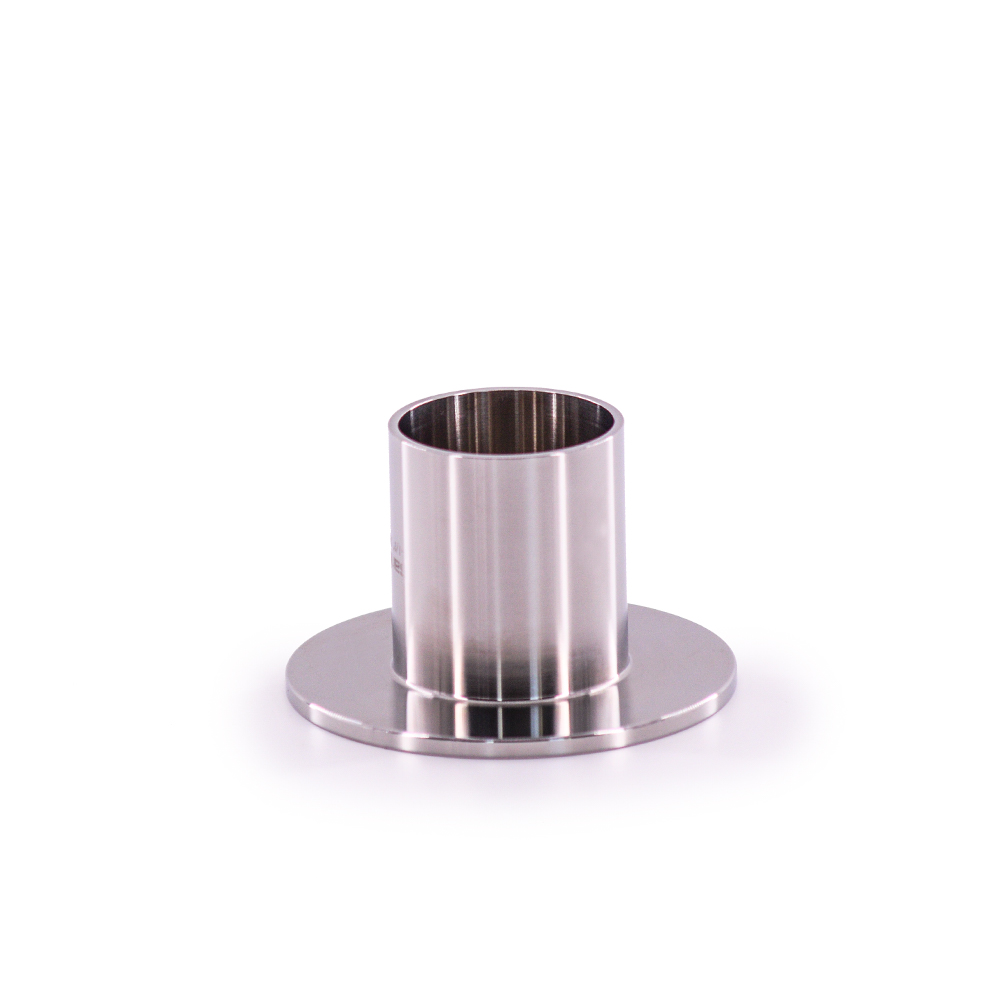

Type A (VB) Stub End – Stainless Steel – 14VB

Price range: $31.90 through $990.95Select options This product has multiple variants. The options may be chosen on the product page -

45° Automatic Weld Elbow – Stainless Steel – AW2KS

Price range: $26.30 through $117.50Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld Cross – Stainless Steel – 9W

Price range: $60.50 through $912.25Select options This product has multiple variants. The options may be chosen on the product page -

Tube OD x Schedule 5s Weld Adapter – Stainless Steel – 19WV

Price range: $23.10 through $154.15Select options This product has multiple variants. The options may be chosen on the product page -

Butt Weld 180° Return – Stainless Steel – 2WUL

Price range: $74.75 through $610.60Select options This product has multiple variants. The options may be chosen on the product page -

End of content

End of content