Light Duty Tank Weld Ferrule – Stainless Steel – 14WLMP

Price range: $12.70 through $275.30

- Sanitary Stainless Light Duty Tank Weld Ferrule

- Available in 304 & 316L Stainless Steel

- 3-A Sanitary Standard (Minimum polish 32 RA)

- Ideal for Food & Beverage, Pharmaceutical and Thermal Management

- Stamped with Heat Lot Numbers

Light Duty Tank Weld Ferrule – Stainless Steel 14WLMP

The Light Duty Tank Weld Ferrule is a premium hygienic connection solution engineered for sanitary process systems. Manufactured from high-quality 304 and 316L stainless steel, this ferrule is built to meet strict 3-A Sanitary Standards and polished to a minimum of 32 RA to maintain sanitary integrity in critical applications, including food & beverage, pharmaceutical, and beverage processing. This ferrule provides a dependable weld connection while ensuring minimal crevices for easy cleaning and long-term corrosion resistance. Each unit is heat lot stamped for traceability and quality assurance.Key Features & Benefits

- Sanitary-Grade Stainless Steel — 304 / 316L options for corrosion resistance and durability.

- 3-A Certified for hygienic applications requiring stringent cleanliness standards.

- Polished Finish (32 RA) — promotes easy clean-in-place (CIP).

- Traceable Heat Lot Marking for quality control.

- Versatile Sizes available from 1/2″ to 8″ tube OD.

Applications

This light duty ferrule is ideal for sanitary process systems such as: ✔ Brewery & Winery Tank Outlets ✔ Food & Beverage Processing Lines ✔ Pharmaceutical and Bioprocess Equipment ✔ Beverage Filtration & Storage SystemsMaterial Options

- 304 Stainless Steel — excellent general-purpose corrosion resistance.

- 316L Stainless Steel — enhanced corrosion resistance, preferred in aggressive environments.

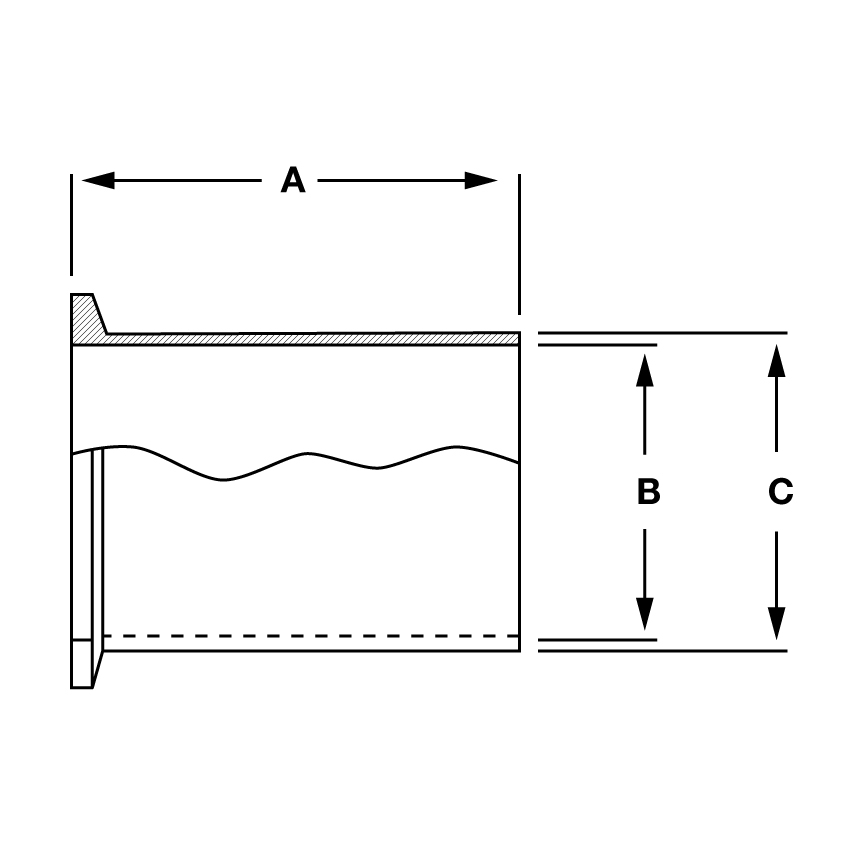

| Size (Tube OD) | Part Number | Dimensions | |||||

| 304L | 316L | A | B | C | |||

| 1/2″ | — | 14WLMP6-050 | 3.000 | 0.370 | 0.500 | ||

| 3/4″ | — | 14WLMP6-075 | 3.000 | 0.620 | 0.750 | ||

| 1″ | 14WLMP4-100 | 14WLMP6-100 | 3.000 | 0.870 | 1.000 | ||

| 1-1/2″ | 14WLMP4-150 | 14WLMP6-150 | 3.000 | 1.370 | 1.500 | ||

| 2″ | 14WLMP4-200 | 14WLMP6-200 | 3.000 | 1.870 | 2.000 | ||

| 2-1/2″ | 14WLMP4-250 | 14WLMP6-250 | 3.000 | 2.370 | 2.500 | ||

| 3″ | 14WLMP4-300 | 14WLMP6-300 | 4.000 | 2.870 | 3.000 | ||

| 4″ | 14WLMP4-400 | 14WLMP6-400 | 4.000 | 3.834 | 4.000 | ||

| 6″ | 14WLMP4-600 | 14WLMP6-600 | 6.000 | 5.782 | 6.000 | ||

| 8″ | 14WLMP4-800 | 14WLMP6-800 | 6.000 | 7.760 | 8.000 | ||

| DuvaSanitary.com | Steel & O’Brien | Dixon | Sanitary Solutions | Wayland | VNE | |

|---|---|---|---|---|---|---|

| 14WLMP | 14WLMP | 14WLMP | SS14WLMP | 14WLMP | EG14WL | |

| 316L | 316L | 316L | 316L | 316L | 316L | |

| 1/2″ | 14WLMP6-050 | 14WLMP-.50-316 | 14WLMP-R50 | SS14WLMP-.50-316 | W614WLMP-.50 | |

| 3/4″ | 14WLMP6-075 | 14WLMP-.75-316 | 14WLMP-R75 | SS14WLMP-.75-316 | W614WLMP-.75 | |

| 1″ | 14WLMP6-100 | 14WLMP-1-316 | 14WLMP-R100 | SS14WLMP-1-316 | W614WLMP-1 | EG14WL-6L1.0 |

| 1-1/2″ | 14WLMP6-150 | 14WLMP-1.5-316 | 14WLMP-R150 | SS14WLMP-1.5-316 | W614WLMP-15 | EG14WL-6L1.5 |

| 2″ | 14WLMP6-200 | 14WLMP-2-316 | 14WLMP-R200 | SS14WLMP-2-316 | W614WLMP-2 | EG14WL-6L2.0 |

| 2-1/2″ | 14WLMP6-250 | 14WLMP-2.5-316 | 14WLMP-R250 | SS14WLMP-2.5-316 | W614WLMP-25 | EG14WL-6L2.5 |

| 3″ | 14WLMP6-300 | 14WLMP-3-316 | 14WLMP-R300 | SS14WLMP-3-316 | W614WLMP-3 | EG14WL-6L3.0 |

| 4″ | 14WLMP6-400 | 14WLMP-4-316 | 14WLMP-R400 | SS14WLMP-4-316 | W614WLMP-4 | EG14WL-6L4.0 |

| 6″ | 14WLMP6-600 | 14WLMP-6-316 | 14WLMP-R600 | SS14WLMP-6-316 | W614WLMP-6 | EG14WL-6L6.0 |

| 8″ | 14WLMP6-800 | 14WLMP-8-316 | 14WLMP-R800 | SS14WLMP-8-316 | W614WLMP-8 | EG14WL-6L8.0 |

| DuvaSanitary.com | Steel & O’Brien | Dixon | Sanitary Solutions | Wayland | VNE | |

|---|---|---|---|---|---|---|

| 14WLMP | 14WLMP | 14WLMP | SS14WLMP | 14WLMP | EG14WL | |

| 304 | 304 | 304 | 304 | 304 | 304 | |

| 1″ | 14WLMP4-100 | 14WLMP-1-304 | 14WLMP-G100 | SS14WLMP-1-304 | W414WLMP-1 | EG14WL1.0 |

| 1-1/2″ | 14WLMP4-150 | 14WLMP-1.5-304 | 14WLMP-G150 | SS14WLMP-1.5-304 | W414WLMP-15 | EG14WL1.5 |

| 2″ | 14WLMP4-200 | 14WLMP-2-304 | 14WLMP-G200 | SS14WLMP-2-304 | W414WLMP-2 | EG14WL2.0 |

| 2-1/2″ | 14WLMP4-250 | 14WLMP-2.5-304 | 14WLMP-G250 | SS14WLMP-2.5-304 | W414WLMP-25 | EG14WL2.5 |

| 3″ | 14WLMP4-300 | 14WLMP-3-304 | 14WLMP-G300 | SS14WLMP-3-304 | W414WLMP-3 | EG14WL3.0 |

| 4″ | 14WLMP4-400 | 14WLMP-4-304 | 14WLMP-G400 | SS14WLMP-4-304 | W414WLMP-4 | EG14WL4.0 |

| 6″ | 14WLMP4-600 | 14WLMP-6-304 | 14WLMP-G600 | SS14WLMP-6-304 | W414WLMP-6 | EG14WL6.0 |

| 8″ | 14WLMP4-800 | 14WLMP-8-304 | 14WLMP-G800 | SS14WLMP-8-304 | W414WLMP-8 | EG14WL8.0 |

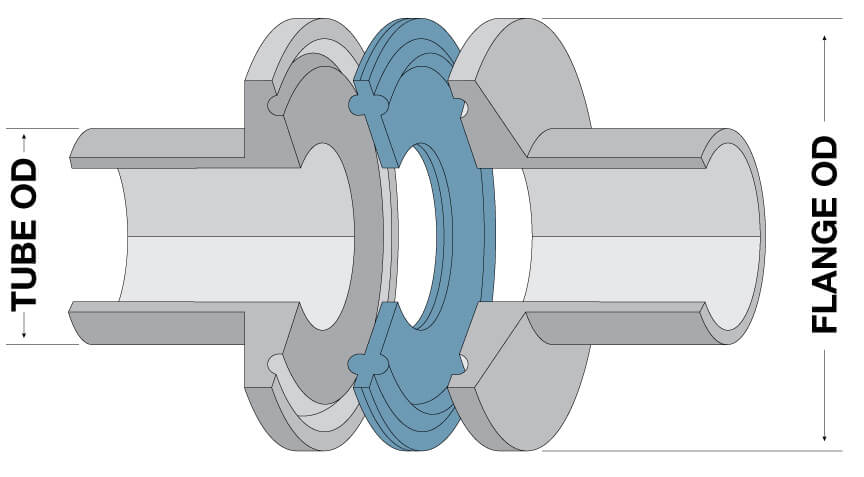

How to Size a Tri-Clover/Tri-Clamp Fitting.

Have you ever wondered how to choose the correct Tri-Clamp size? Or how to measure an existing Tri-Clamp fitting?

The sizing is based on the outside diameter (OD) of the tube, not on the outside diameter (OD) of the flange.

For example:

- If your tube OD measurement is 2 inches, then your Tri-Clamp size is 2”.

- If your existing Tri-Clamp fitting’s flange measures approximately 2.5 inches OD (2.516”), then your Tri-Clamp size is 2”.

Consult the chart below for corresponding Size / Tube OD and Flange OD measurements.

Note:

- Sizes ½” and ¾” have the same flange OD of approximately 1 inch (0.984”).

- Sizes 1” and 1-1/2” have the same flange OD of approximately 2 inches (1.984”).

Tri-Clamp Fitting Size Chart.

| Tri-Clamp Size / Tube OD | Tri-Clamp Flange OD |

|---|---|

| 1/2″ & 3/4″ | 0.984″ |

| 1″ & 1-1/2″ | 1.984″ |

| 2″ | 2.516″ |

| 2.5″ | 3.047″ |

| 3″ | 3.579″ |

| 4″ | 4.682″ |

| 6” | 6.570” |

| 8” | 8.602” |

| 10” | 10.570” |

| 12” | 12.570” |