Tube Slip-On Flange – Stainless Steel – B38SL

Price range: $35.40 through $454.65

- Sanitary Stainless Tube Slip-On Flange

- Available in 304 & 316L Stainless Steel

- Sanitary Grade (Minimum polish 32 RA)

- Ideal for Food & Beverage and Pharmaceutical Markets

- Stamped with Heat Lot Numbers

- Available materials: 304 & 316L stainless steel for corrosion resistance.

- Traceability: Each part is heat lot stamped for quality assurance.

- Applications: Food processing, beverage lines, pharmaceutical production, CIP systems.

Key Features & Benefits

- Ease of Installation: Slides onto tube with minimal prep, speeding up fit-up and alignment.

- Cost-Effective Solution: Lower manufacturing and installation costs compared to complex flange types.

- Versatility: Works with a wide range of tube sizes and sanitary welding configurations.

- Durable & Reliable: Ideal for lower- to medium-pressure sanitary pipelines.

Technical Specifications

| Feature | Details |

| Available Grades | 304 & 316L SS |

| Surface Finish | 32 RA minimum |

| Sanitary Standard | FDA-suitable for hygienic use |

| Bolt Pattern | Standard industry pattern compatible with sanitary fittings |

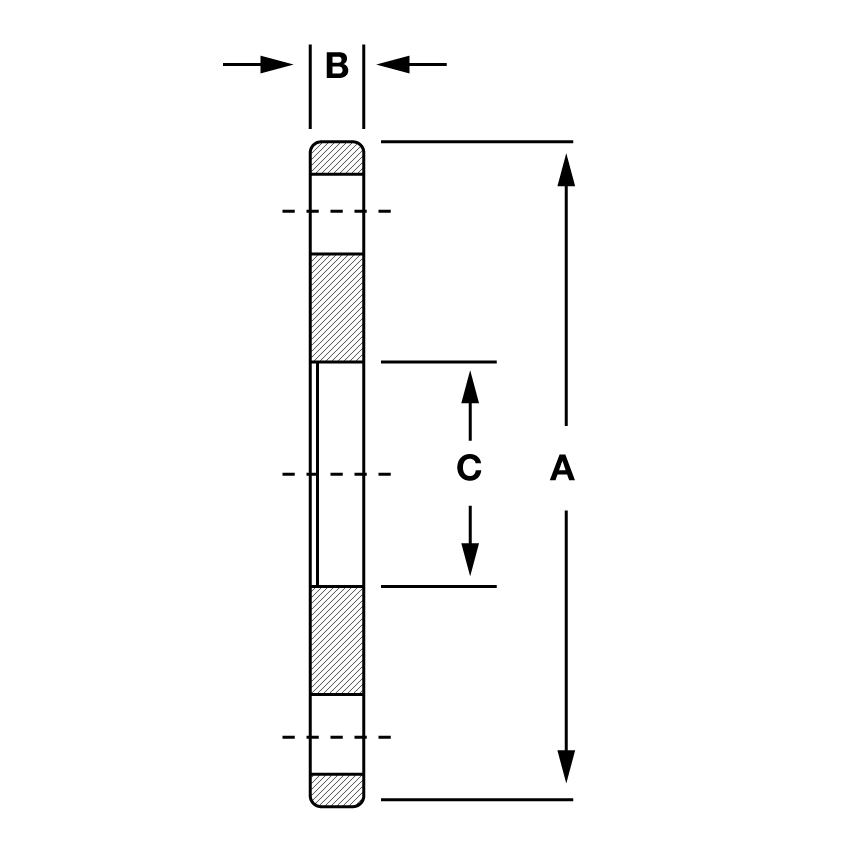

| Size (Tube OD) | Part Number | Dimensions | Holes | |||||

|---|---|---|---|---|---|---|---|---|

| 304 | 316L | A | B | C | D | Diameter | Count | |

| 1″ | 38SL4-100 | 38SL6-100 | 4.250 | 0.500 | 1.031 | 3.125 | 5/8″ | 4 |

| 1-1/2″ | 38SL4-150 | 38SL6-150 | 5.000 | 0.500 | 1.531 | 3.875 | 5/8″ | 4 |

| 2″ | 38SL4-200 | 38SL6-200 | 6.000 | 0.500 | 2.031 | 4.750 | 3/4″ | 4 |

| 2-1/2″ | 38SL4-250 | 38SL6-250 | 7.000 | 0.500 | 2.531 | 5.500 | 3/4″ | 4 |

| 3″ | 38SL4-300 | 38SL6-300 | 7.500 | 0.500 | 3.031 | 6.000 | 3/4″ | 4 |

| 4″ | 38SL4-400 | 38SL6-400 | 9.000 | 0.500 | 4.031 | 7.500 | 3/4″ | 8 |

| 5″ | 38SL4-500 | 38SL6-500 | 10.000 | 0.500 | 5.031 | 8.500 | 3/4″ | 8 |

| 6″ | 38SL4-600 | 38SL6-600 | 11.000 | 0.500 | 6.031 | 9.500 | 7/8″ | 8 |

| 8″ | 38SL4-800 | 38SL6-800 | 13.500 | 0.500 | 8.031 | 11.750 | 7/8″ | 8 |

| 10″ | 38SL4-1000 | 38SL6-1000 | 16.000 | 0.500 | 10.031 | 14.250 | 1 “ | 12 |

| 12″ | 38SL4-1200 | 38SL6-1200 | 19.000 | 0.500 | 12.063 | 17.000 | 1 “ | 12 |

| DuvaSanitary.com | Steel & O’Brien | Wayland | VNE | Sanitary Solutions | |

|---|---|---|---|---|---|

| B38SL | 38SL | 38SL | E38SL | SS38SL | |

| 316L | 316L | 316L | 316L | 316L | |

| 1/2″ | B38SL-R050 | 38SL-.50-316 | W638SL-.50 | SS38SL-0.50-316L | |

| 3/4″ | B38SL-R075 | 38SL-.75-316 | W638SL-.75 | SS38SL-.75-316L | |

| 1″ | B38SL-R100 | 38SL-1-316 | W638SL-1 | SS38SL-1-316L | |

| 1-1/2″ | B38SL-R150 | 38SL-1.5-316 | W638SL-15 | SS38SL-1.5-316L | |

| 2″ | B38SL-R200 | 38SL-2-316 | W638SL-2 | SS38SL-2-316L | |

| 2-1/2″ | B38SL-R250 | 38SL-2.5-316 | W638SL-25 | SS38SL-2.5-316L | |

| 3″ | B38SL-R300 | 38SL-3-316 | W638SL-3 | SS38SL-3-316L | |

| 4″ | B38SL-R400 | 38SL-4-316 | W638SL-4 | SS38SL-4-316L | |

| 6″ | B38SL-R600 | 38SL-6-316 | W638SL-6 | SS38SL-6-316L | |

| 8″ | B38SL-R800 | 38SL-8-316 | W638SL-8 | SS38SL-8-316L |

| DuvaSanitary.com | Steel & O’Brien | Wayland | VNE | Sanitary Solutions | |

|---|---|---|---|---|---|

| B38SL | 38SL | 38SL | E38SL | SS38SL | |

| 304 | 304 | 304 | 304 | 304 | |

| 1/2″ | B38SL-G050 | 38SL-.50-316 | W438SL-.50 | SS38SL-0.50-304 | |

| 3/4″ | B38SL-G075 | 38SL-.75-316 | W438SL-.75 | SS38SL-.75-304 | |

| 1″ | B38SL-G100 | 38SL-1-304 | W438SL-1 | E38SL1.0 | SS38SL-1-304 |

| 1-1/2″ | B38SL-G150 | 38SL-1.5-304 | W438SL-15 | E38SL1.5 | SS38SL-1.5-304 |

| 2″ | B38SL-G200 | 38SL-2-304 | W438SL-2 | E38SL2.0 | SS38SL-2-304 |

| 2-1/2″ | B38SL-G250 | 38SL-2.5-304 | W438SL-25 | E38SL2.5 | SS38SL-2.5-304 |

| 3″ | B38SL-G300 | 38SL-3-304 | W438SL-3 | E38SL3.0 | SS38SL-3-304 |

| 4″ | B38SL-G400 | 38SL-4-304 | W438SL-4 | E38SL4.0 | SS38SL-4-304 |

| 6″ | B38SL-G600 | 38SL-6-304 | W438SL-6 | SS38SL-6-304 | |

| 8″ | B38SL-G800 | 38SL-8-304 | W438SL-8 | SS38SL-8-304 | |

| 10″ | B38SL-G1000 | 38SL-10-304 | W438SL-10 | ||

| 12″ | B38SL-G1200 | 38SL-12-304 | W438SL-12 |

What is a tube slip-on flange used for?

A tube slip-on flange is used to connect sanitary tubing sections in food, beverage, and pharmaceutical piping systems. It slides onto the tube and is bolted into place for secure, sanitary connections.

Why choose 316L stainless steel over 304?

316L offers improved corrosion resistance in high-purity and harsh environments, making it ideal for pharmaceutical and high-sanitation food processing applications.

How is a slip-on flange installed?

Slip-on flanges are aligned over tube OD, fillet welded on both inner and outer diameters, and fastened into the system. This design simplifies alignment and reduces installation time.

Can I use this flange in high-pressure applications?

Slip-on flanges are typically suited for low- to medium-pressure sanitary systems; consult project specs for pressure ratings.

You may also like…

-

Type A (VB) Stub End – Stainless Steel – 14VB

Price range: $31.90 through $990.95Select options This product has multiple variants. The options may be chosen on the product page -

Flange Gasket Bolt Kit – Stainless Steel – K404T

Price range: $10.70 through $89.97Select options This product has multiple variants. The options may be chosen on the product page