Stainless Steel Sanitary Tubing – Stainless Steel – SSST

High-Quality Stainless Steel Sanitary Tubing for Precision and Hygiene

Our bright annealed polished stainless steel sanitary tubing is engineered to meet the highest sanitary standards, including ASTM A270 and 3-A Sanitary Standards, ensuring it’s suitable for critical applications in the food, beverage, pharmaceutical, and biotechnology industries. Available in premium 304 and 316L stainless steel options, this tubing provides exceptional durability and corrosion resistance.

Key Features

- Precision Interior and Exterior Finish: The interior surface of the tubing is polished to 20RA (180 grit), while the exterior is finished to 32RA (150 grit), maximizing both aesthetic appeal and cleanliness.

- Cold Rolled Stainless Steel Construction: Manufactured from high-quality cold rolled stainless steel strip, our tubing undergoes a precise chemical control process, ensuring optimal weldability.

- Seamless Longitudinal Weld: The tubing’s weld bead is cold-worked to create a smooth, virtually undetectable weld, resulting in enhanced structural integrity and aesthetic continuity.

- Bright Annealing Process: Each tube is bright annealed to a minimum of 1,900°F in a controlled atmosphere, enhancing its structural strength and long-term performance.

- Clear Marking for Traceability: Our tubing is line-stenciled with outer diameter, wall thickness, ASTM specs, grade, and heat number for complete product traceability.

Order and Shipping Information

Our stainless steel sanitary tubing is sold in case quantities, and individual lengths are also available upon request. Due to its weight and special handling requirements, this item does not qualify for free shipping. Once your order is placed, we will contact you to arrange the most efficient and cost-effective freight options.

Applications

Ideal for applications demanding high levels of hygiene and corrosion resistance, this sanitary tubing is trusted by professionals for use in:

- Food and beverage processing

- Pharmaceutical manufacturing

- Biotechnology systems

- Dairy and other sanitary processing environments

Duva Sanitary’s Stainless Steel Sanitary Tubing provides a seamless, polished finish designed for maximum purity. Ideal for fluid transport in sanitary applications, our tubing maintains corrosion resistance, meeting strict industry standards.

To get a quote on custom lengths or case quantities, please call or email our team. Elevate your sanitary systems with our reliable, meticulously crafted stainless steel sanitary tubing—built to exceed industry standards and your expectations.

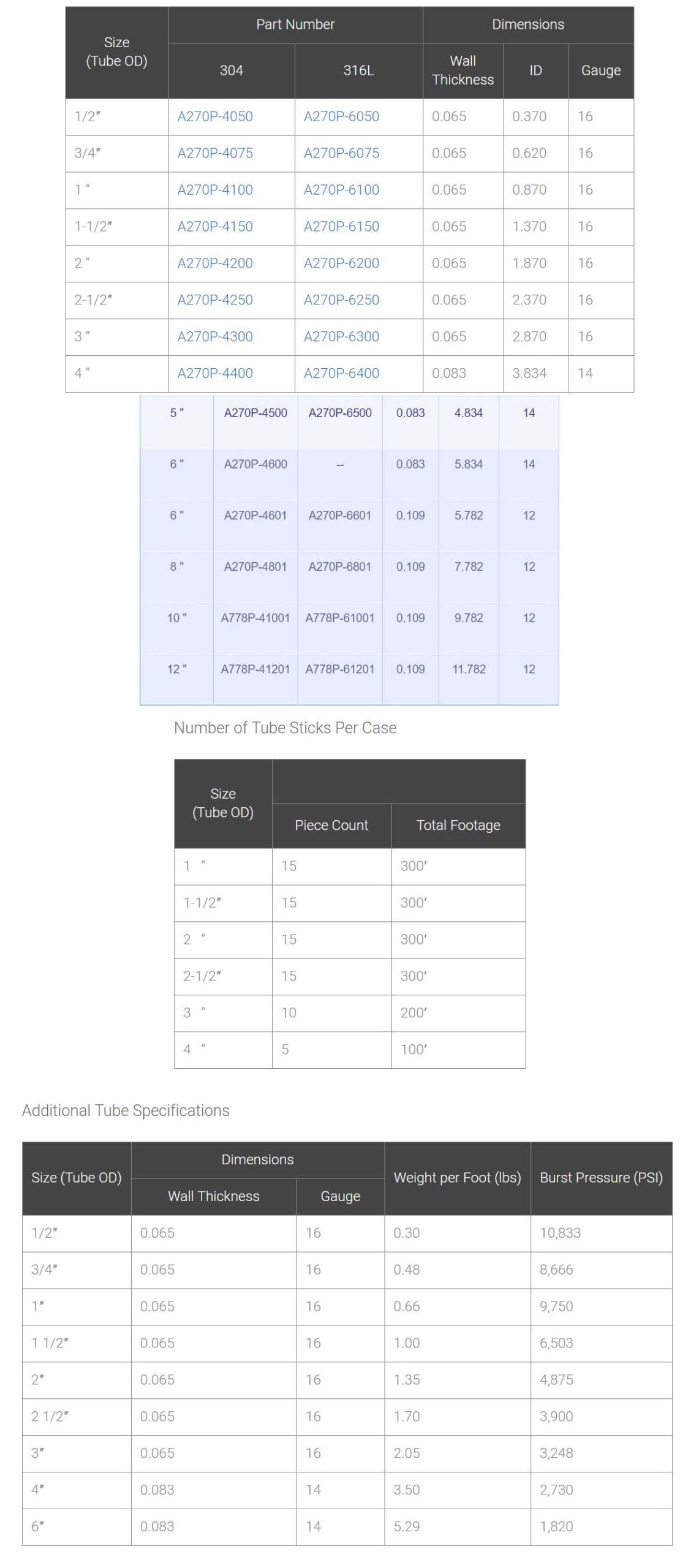

| Size | Part Number | Dimensions | Other Specs | ||||

| (Tube OD) | 304 | 316L | Wall Thickness | ID | Gauge | *Lbs./Ft. | *PSI |

| 1/2″ | 78L0865-SAN | 0.065 | 0.37 | 16 | 0.3 | 10833 | |

| 3/4″ | 78L1265-SAN | 0.065 | 0.62 | 16 | 0.475 | 8666 | |

| 1“ | 58L1665-SAN | 78L1665-SAN | 0.065 | 0.87 | 16 | 0.65 | 9750 |

| 1-1/2″ | W58L2465-SAN | W78L2465-SAN | 0.065 | 1.37 | 16 | 0.995 | 6503 |

| 2“ | W58L3265-SAN | W78L3265-SAN | 0.065 | 1.87 | 16 | 1.35 | 4875 |

| 2-1/2″ | W58L4065-SAN | W78L4065-SAN | 0.065 | 2.37 | 16 | 1.7 | 3900 |

| 3“ | W58L4865-SAN | W78L4865-SAN | 0.065 | 2.87 | 16 | 2.035 | 3248 |

| 4″ | W58L6465-SAN | 0.065 | 3.87 | 16 | 2.73 | 2187 | |

| 4“ | W58L6483-SAN | W78L6483-SAN | 0.083 | 3.834 | 14 | 3.47 | 2730 |

| 5″ | W58L8065-SAN | 0.065 | 4.87 | 16 | 3.77 | ||

| 5″ | W78L8083-SAN | 0.083 | 4.834 | 14 | 4.36 | 2184 | |

| 6″ | W58L9683-SAN | 0.083 | 5.834 | 14 | 5.245 | 1820 | |

| 6″ | W58L96109-SAN | W78L96109-SAN | 0.109 | 5.782 | 12 | 6.858 | 2543 |

| 8″ |

W58L128109-SAN

|

W78L128109-SAN

|

0.109 | 7.782 | 12 | 9.27 | 1907 |

| 10″ |

W58L160109-SAN

|

W78L160109-SAN

|

0.109 | 9.782 | 12 | 11.62 | 1526 |

| 12″ |

W58L192109-SAN

|

W78L192109-SAN

|

0.109 | 11.782 | 12 | 13.97 | 1271 |

*denotes theoretical

Number of Tube Sticks Per Case

| Size | Box Quantity | |

| (Tube OD) | Piece Count | Total Footage |

| 1/2“ | 15 | 300′ |

| 3/4″ | 15 | 300′ |

| 1“ | 15 | 300′ |

| 1-1/2″ | 15 | 300′ |

| 2“ | 15 | 300′ |

| 2-1/2″ | 15 | 300′ |

| 3″ | 10 | 200′ |

| 4″ | 5 | 100′ |

| 6″ | 2 | 40′ |

| 8″ | 1 | 20′ |

| Weight | N/A |

|---|---|

| Grade | |

| Size (Tube OD) | 1/2", 3/4", 1", 1-1/2", 2", 2-1/2", 3", 4", 5", 6", 8", 10", 12" |

| Wall Thickness |

What qualifications and expertise does Duva Sanitary have in manufacturing stainless steel sanitary tubing?

Duva Sanitary demonstrates its expertise in manufacturing stainless steel sanitary tubing by adhering to the highest industry standards, including ASTM A270 and 3-A Sanitary Standards. The tubing is crafted from premium 304 and 316L stainless steel, known for its exceptional corrosion resistance and durability. Our process includes a bright annealing treatment in a controlled atmosphere, ensuring enhanced structural integrity. Furthermore, each tube is meticulously marked with its outer diameter, wall thickness, ASTM specifications, grade, and heat number, which guarantees complete traceability and quality assurance.

What quality control procedures are followed during the manufacturing of stainless steel sanitary tubing?

Our stainless steel sanitary tubing is manufactured following stringent quality control procedures to ensure compliance with the highest sanitary standards, such as ASTM A270 and 3-A Sanitary Standards. The tubing undergoes a bright annealing process at a minimum of 1,900°F in a controlled atmosphere to enhance structural integrity. Each tube is meticulously polished to a 32RA (150 grit) finish for optimal cleanliness and aesthetic appeal. For complete traceability, each tube is marked with its outer diameter, wall thickness, ASTM specifications, grade, and heat number.

How can I get a detailed cost estimate and consultation for selecting the appropriate stainless steel sanitary tubing?

To receive a detailed cost estimate and professional consultation for selecting the right stainless steel sanitary tubing, please contact our sales team directly through the contact information provided on our site. Our experts are ready to assist you by discussing your specific requirements, including tubing size, grade, and application, to ensure that you receive a product that meets your sanitary standards and budget. Additionally, we provide guidance on shipping options and any applicable discounts for bulk orders.

What performance and durability can I expect from Duva’s stainless steel sanitary tubing in high-corrosion environments?

Duva’s stainless steel sanitary tubing is designed to perform exceptionally well in high-corrosion environments due to its construction from premium 304 and 316L stainless steel, which offers outstanding corrosion resistance and longevity. The tubing’s surfaces are polished to a 32RA (150 grit) finish, enhancing both cleanliness and aesthetic appeal. Additionally, the bright annealing process at a minimum of 1,900°F in a controlled atmosphere further strengthens its structural integrity, ensuring reliable performance and extended lifespan even in challenging conditions.

You may also like…

-

Hexagonal Tube Hanger with PVC Inserts – Stainless Steel – T24

Price range: $6.25 through $188.40Select options This product has multiple variants. The options may be chosen on the product page -

Hexagonal Tube Hanger with EPDM Grommets – Stainless Steel – T24RG

Price range: $7.65 through $167.45Select options This product has multiple variants. The options may be chosen on the product page